Urethane Casting | Vacuum Casting Services

Custom urethane parts from prototyping to small production runs. ±0.01mm tolerance. 6 days delivery.

Custom urethane parts from prototyping to small production runs. ±0.01mm tolerance. 6 days delivery.

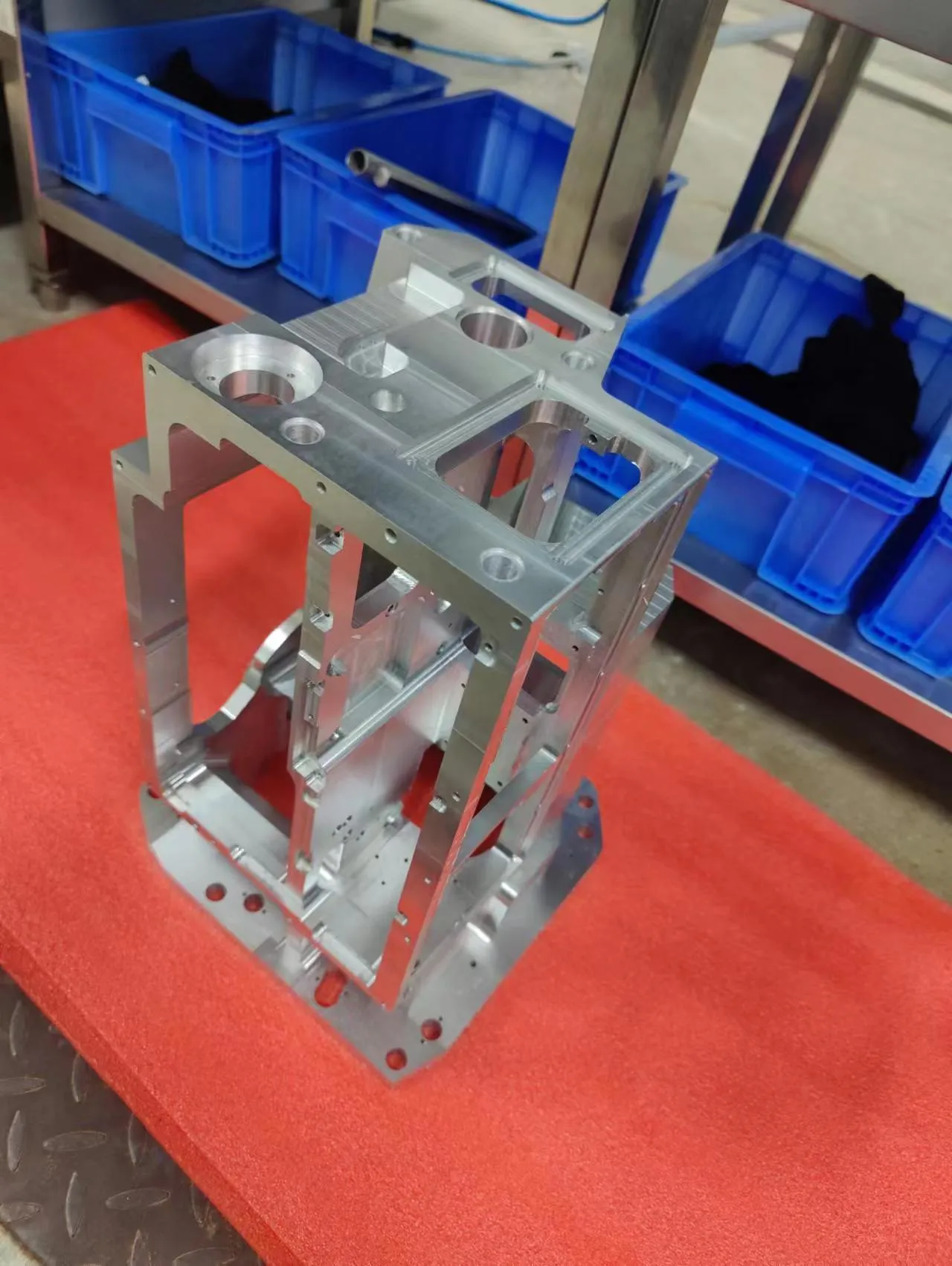

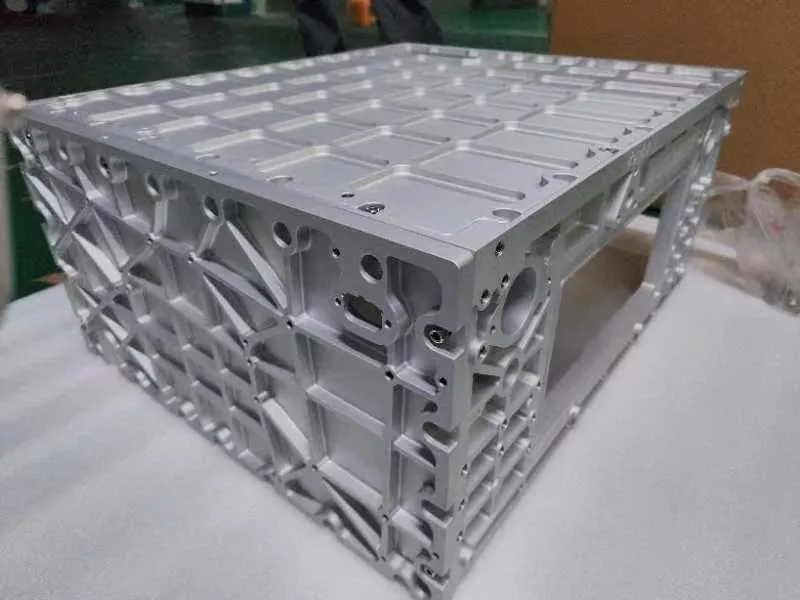

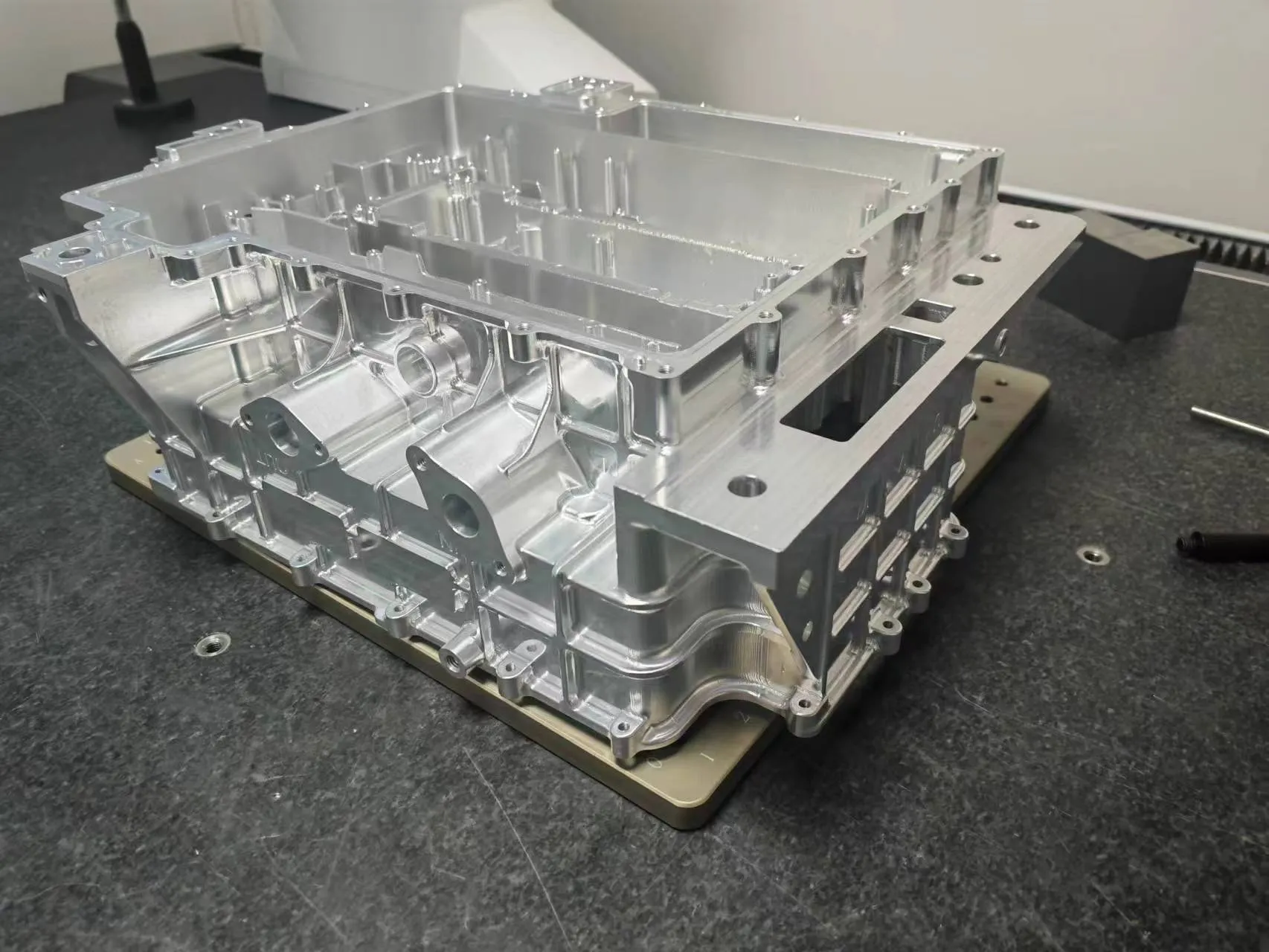

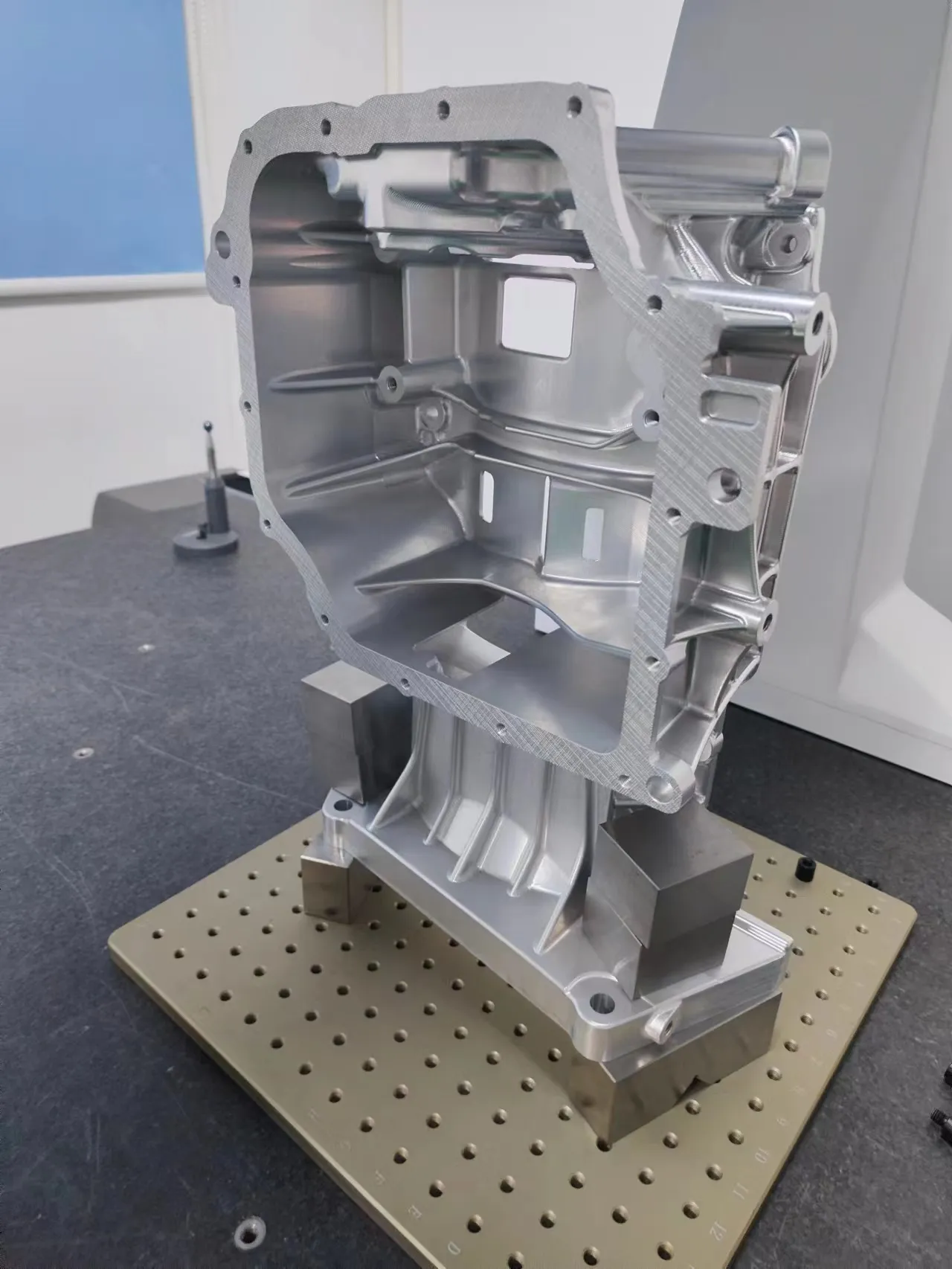

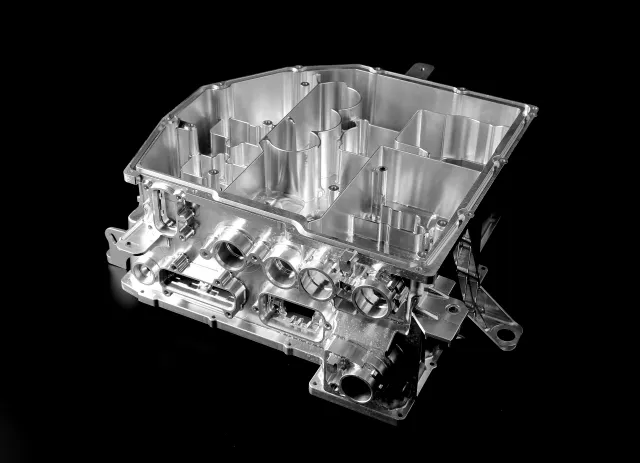

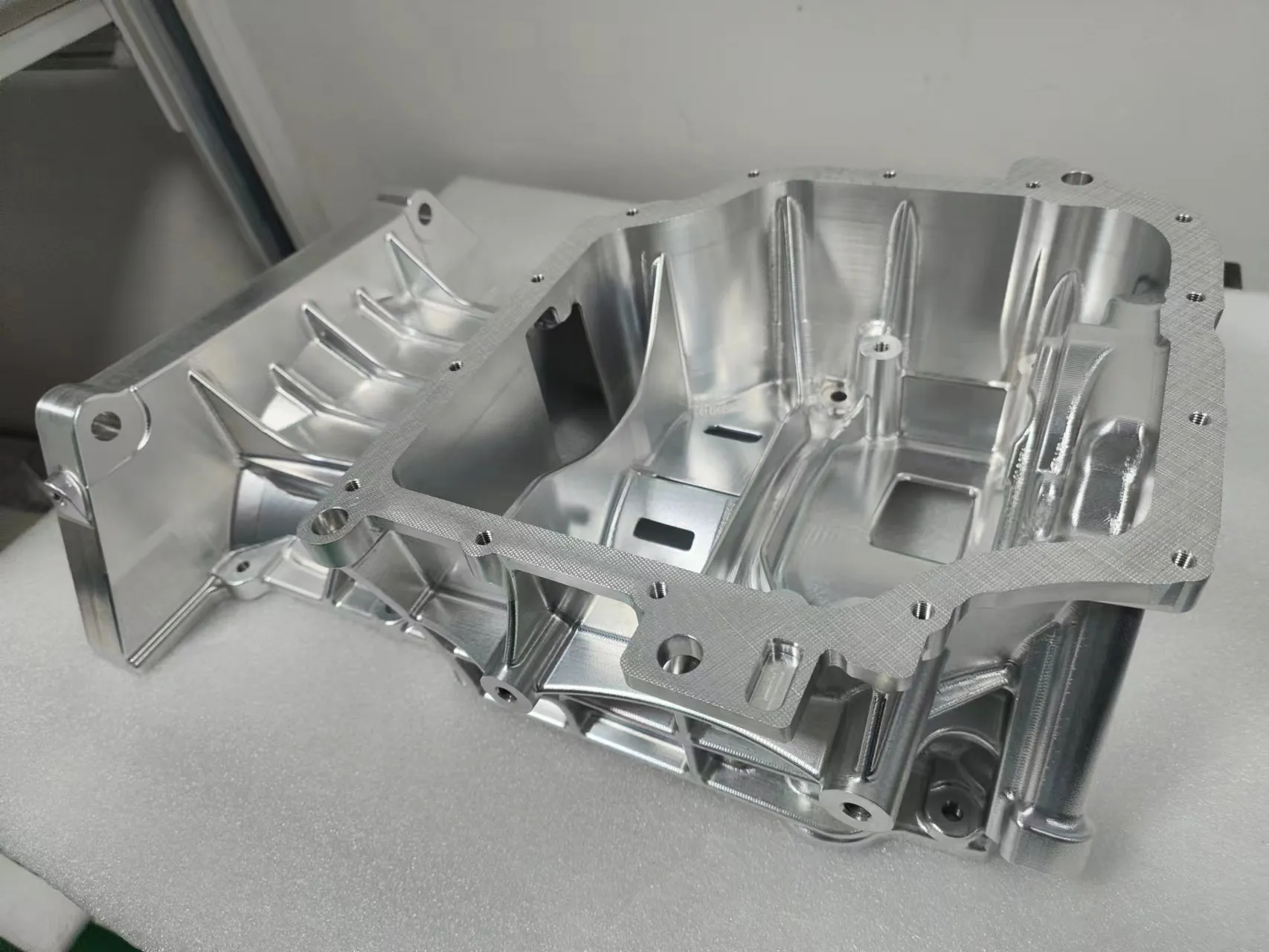

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

CNC-machining-Parts

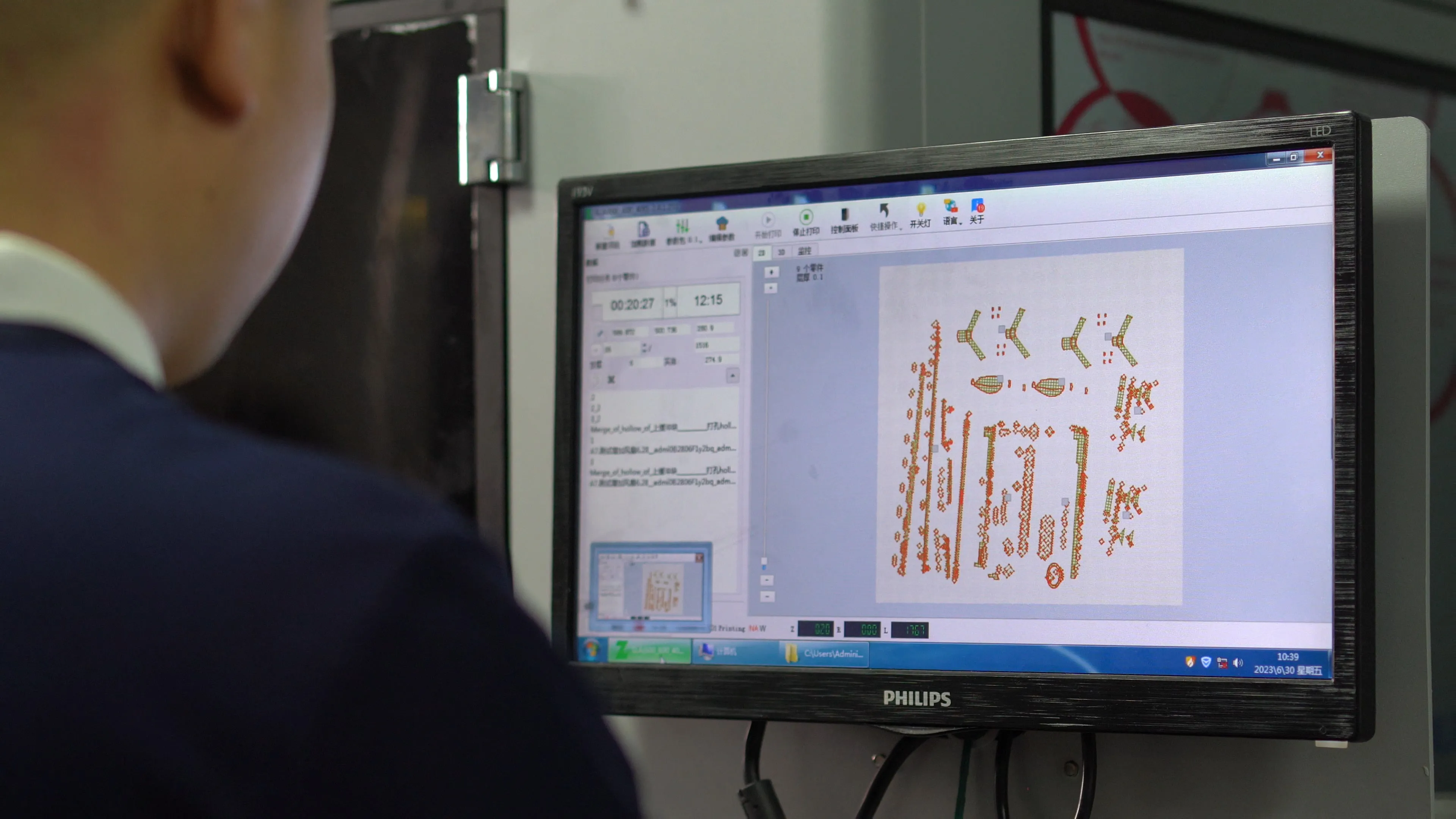

FlagShip’s urethane casting services support every stage from prototype testing, function validation and market testing phases. Operating from ISO-certified facilities and vetted manufacturing partners, we ensure you stay on sechedule and within budget. We cast urethane parts with tolerances down to ±0.10mm and lead times as short as 6 days. A variety of polyurethane and silicone materials, surface finishes, and color options are available for applications in automotive, electronics, and consumer products.

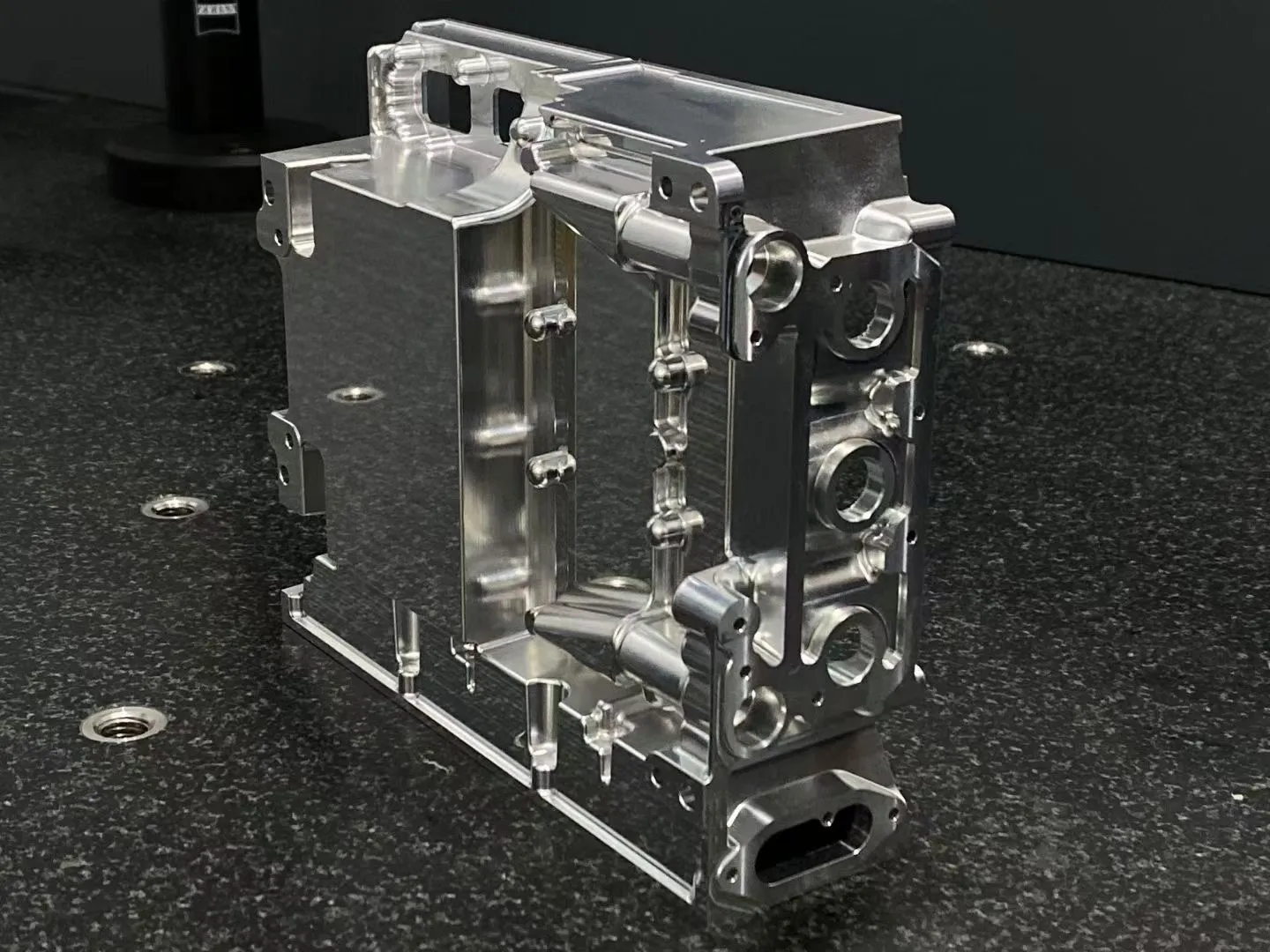

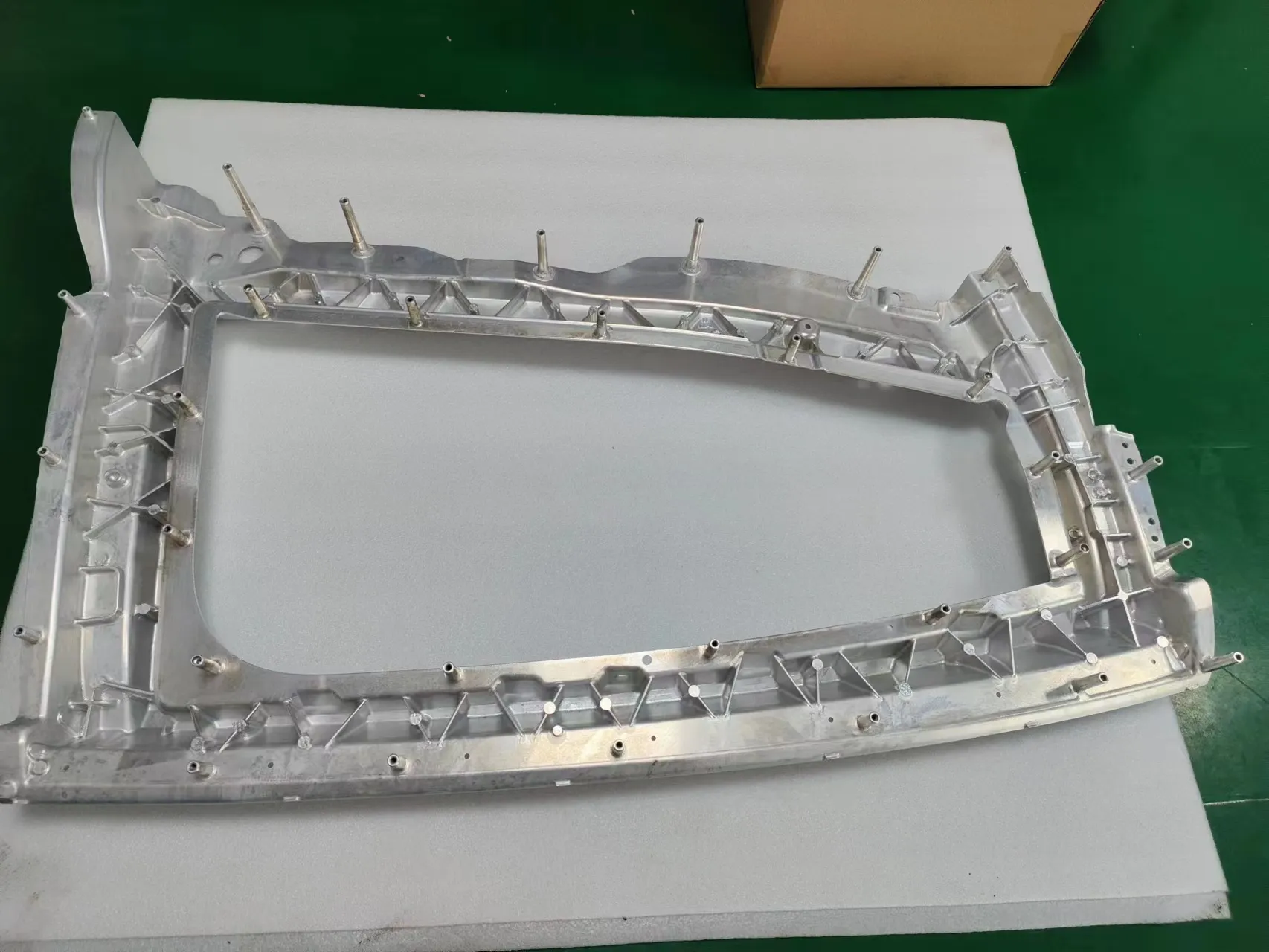

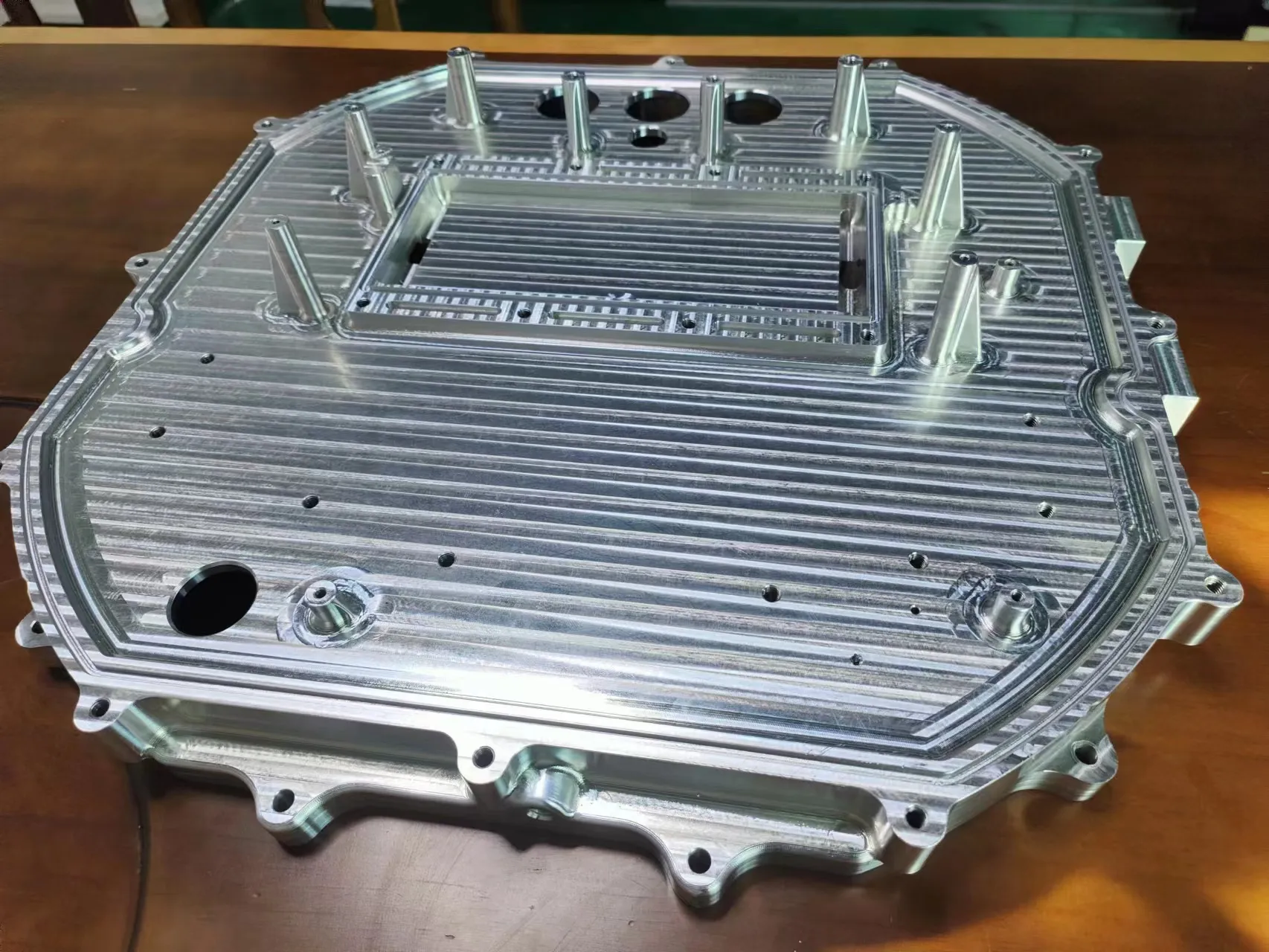

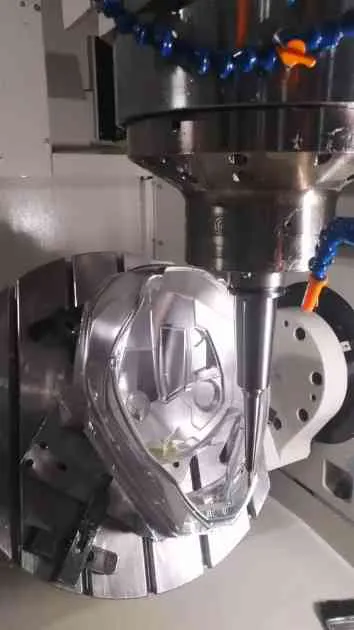

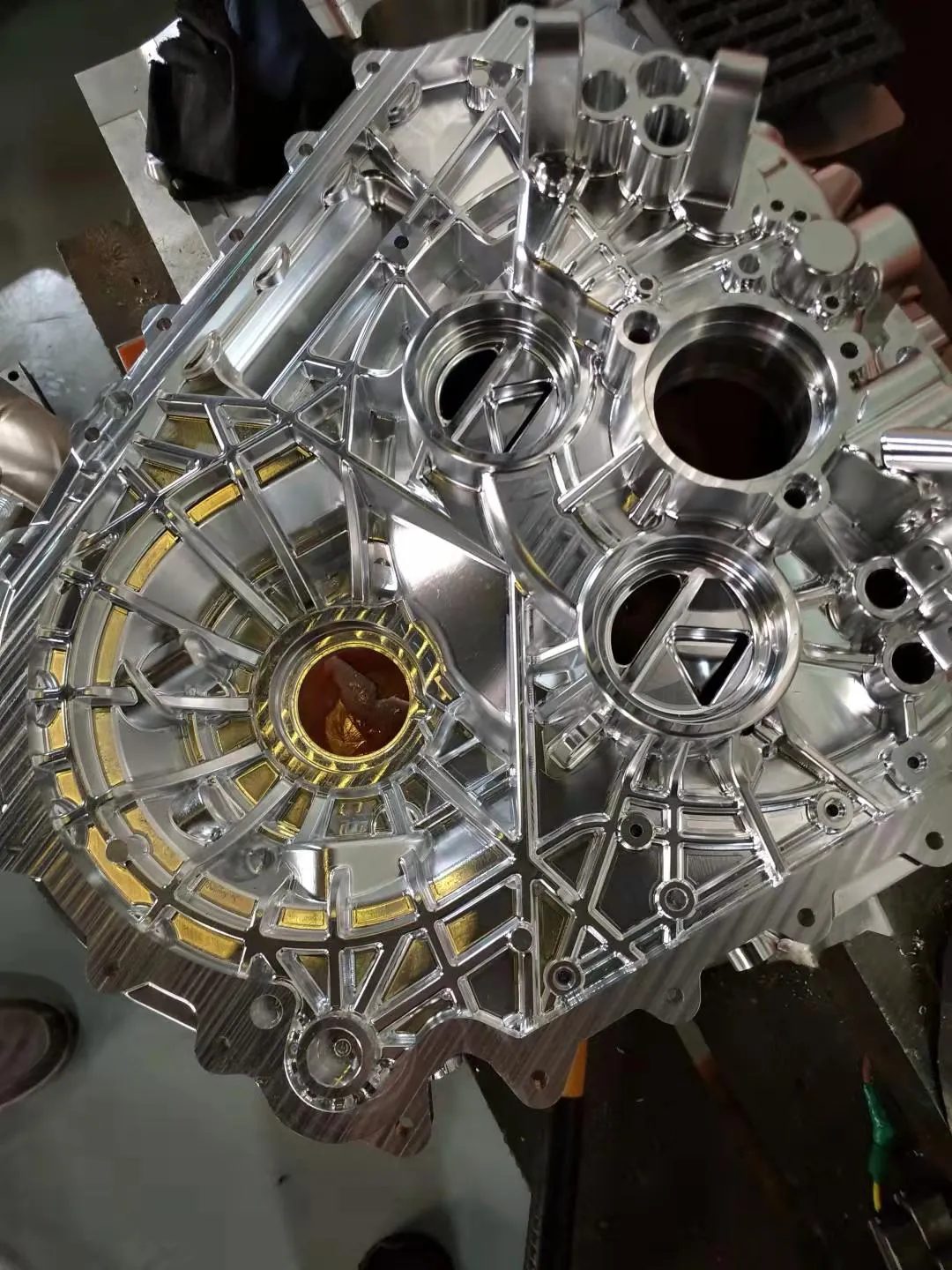

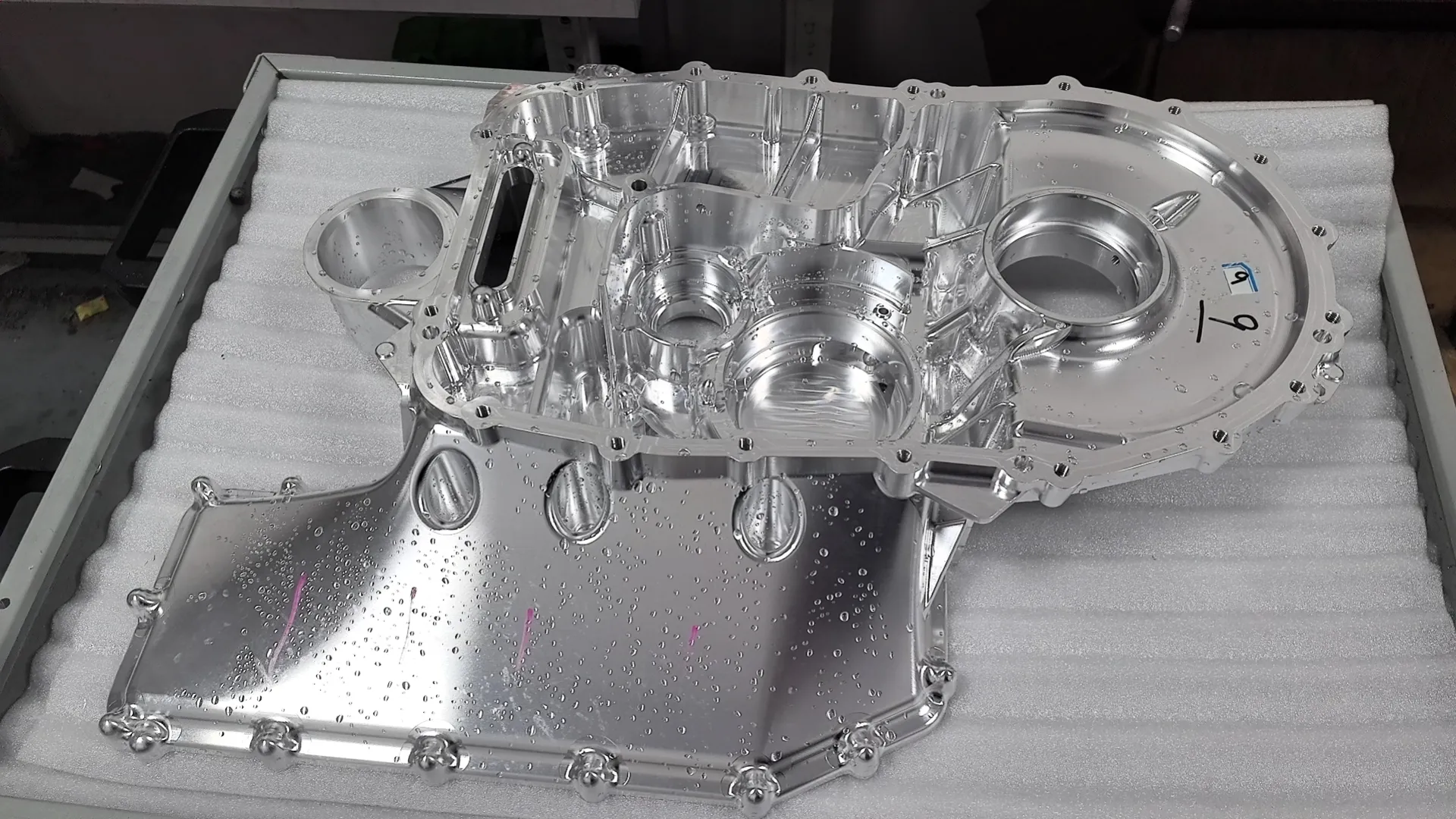

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

Precision Metal Components

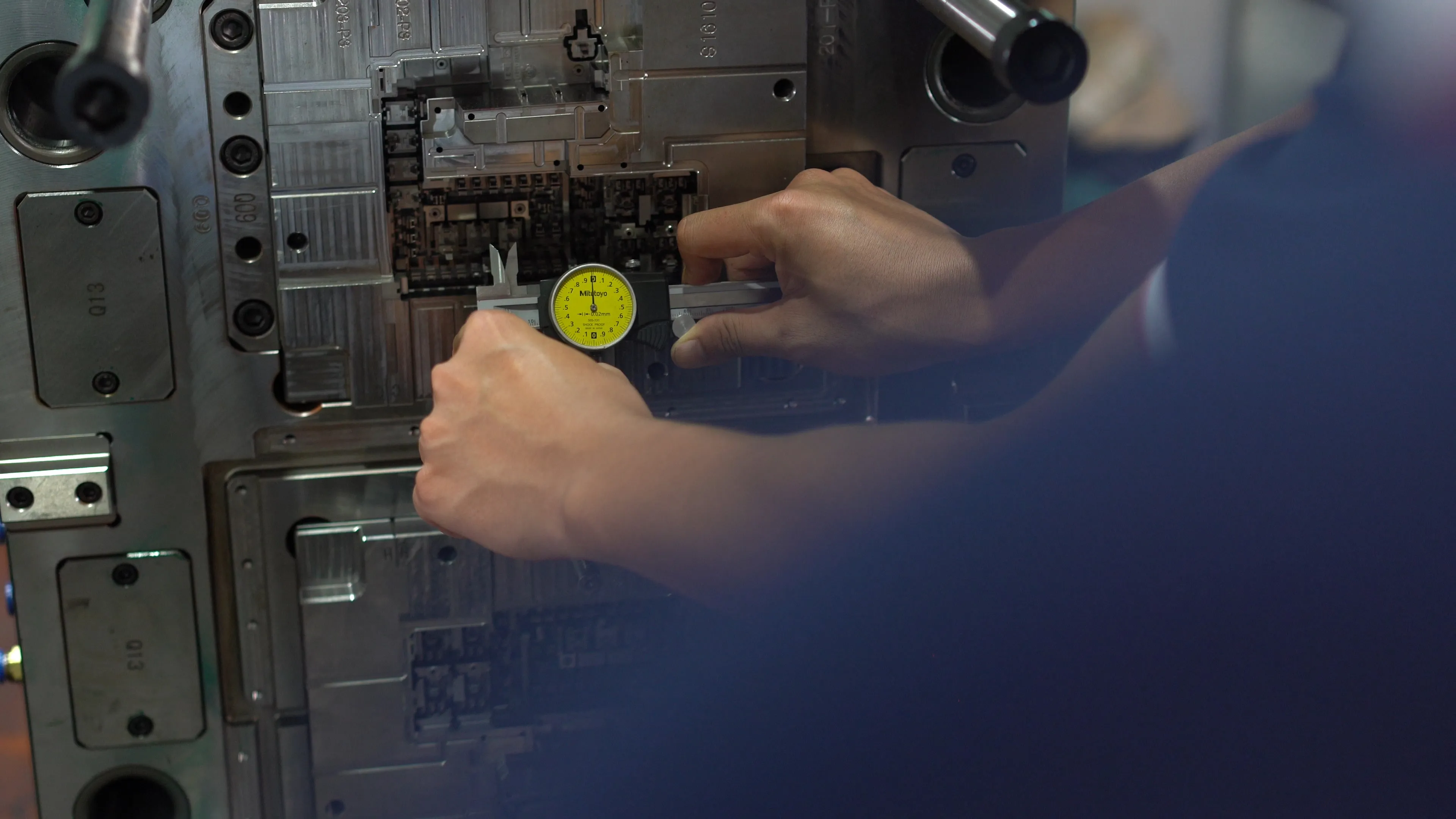

| Feature | Description |

|---|---|

| Tolerance | At FlagShip, replicated casts follow ISO-2768-CL standards. Local tolerances can reach ±0.15mm, and small holes can achieve up to ±0.10mm precision. |

| Color and Finishing | Supports a wide range of colors, transparency levels, and surface finishes. |

| Maximum Part Size | Up to 2.3 × 1.3 × 0.6 meters. |

| Daily Capacity | Up to 200 pieces per day. |

| Lead Time | Lead time varies based on part complexity and order volume. The full process includes prototype making, silicone mold creation, casting, and finishing. Simple single parts can ship in under 5 days, but larger batches may require more time depending on the project. |

Moving from initial concepts to market-ready products, FlagShip’s vacuum casting services offer cost-effective solutions for your product development.

Free shipping available for domestic CNC orders